- Shipping Company Estimated Delivery Time Shipping Cost

- This item cannot be shipped at your location

Highlights

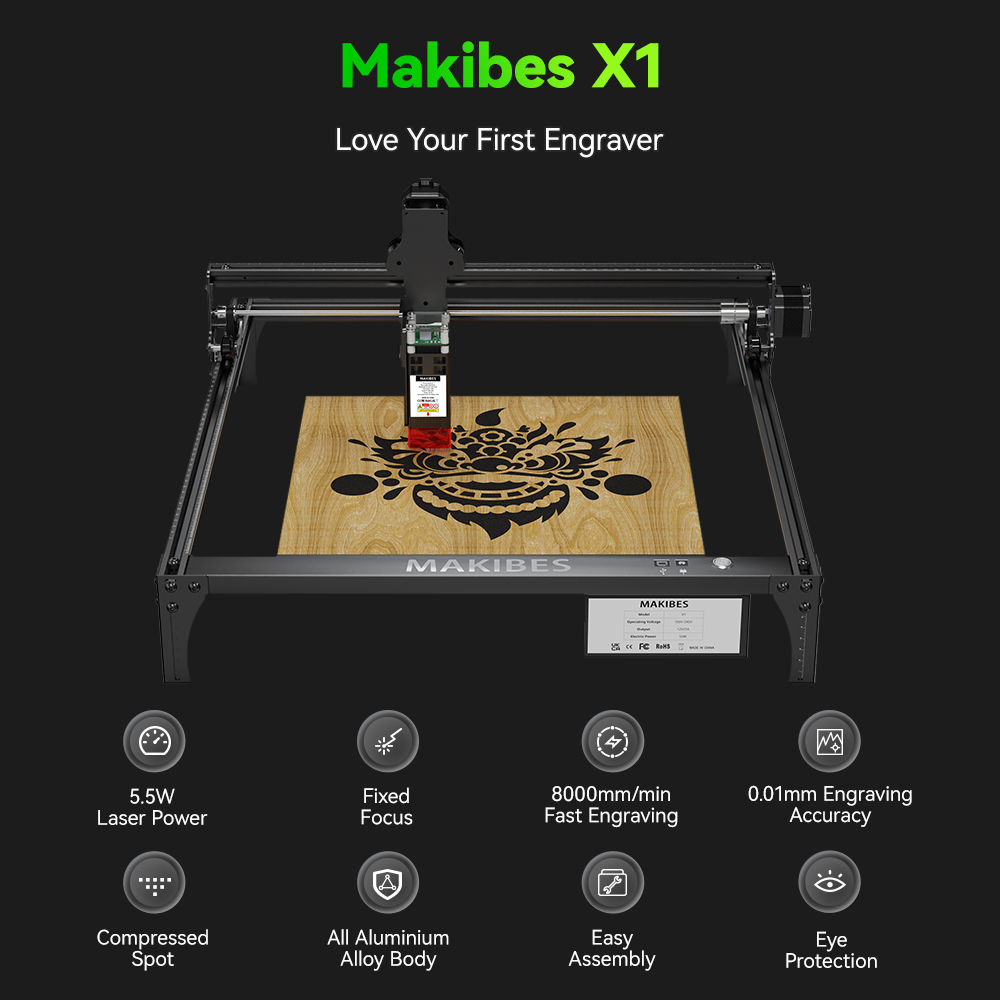

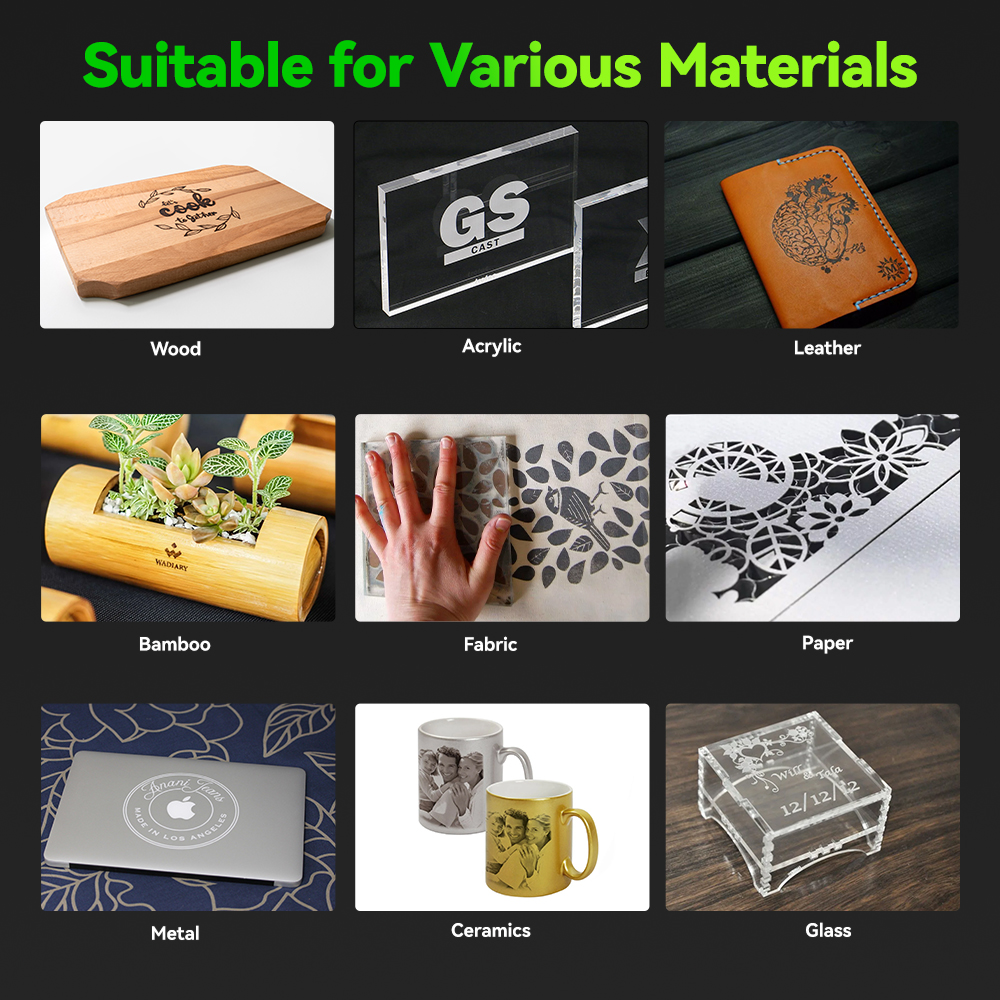

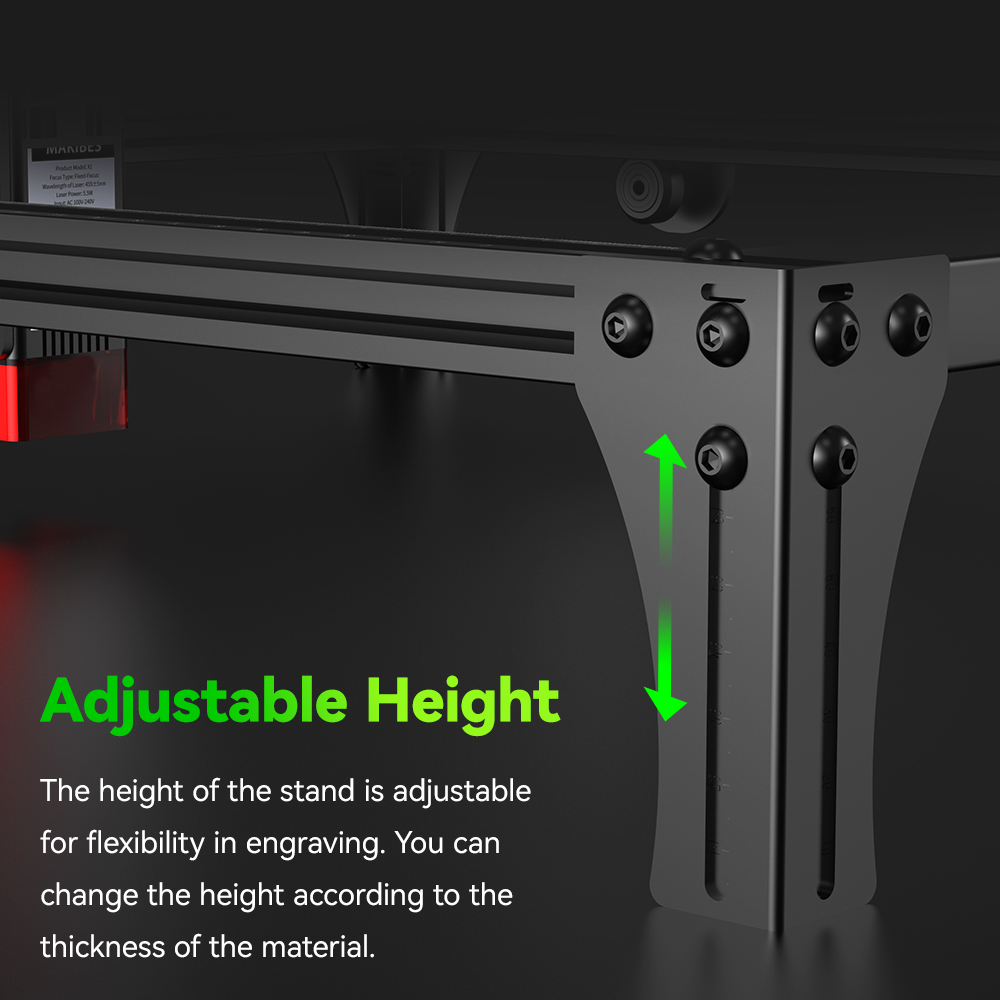

The Makibes X1 is an entry-level laser engraver that houses a diode laser with an ultra-fine compressed spot of 0.07mm*0.08mm to make the laser engraving projects extremely exquisite for both hobbyists and makers alike. With an easy construction manual, the machine can be assembled in less than 30 minutes, even for newbies. The 5-watt laser power allows it to engrave on wood, paper, cardboard, plastic, white, PCB board, aluminum oxide, 304 Stainless steel, ceramic, dark stone, etc, materials. With a full engraving size of 410mm by 400mm, you can let your imagination fly. If in any case, you want to engrave on cylinder objects, or can`t stand the smoke or even smell produced during the engraving process, the majority of the accessories available are compatible with the engraver, like the laser bed, rotary roller, rotary chuck, smoke exhaust or enclosure.

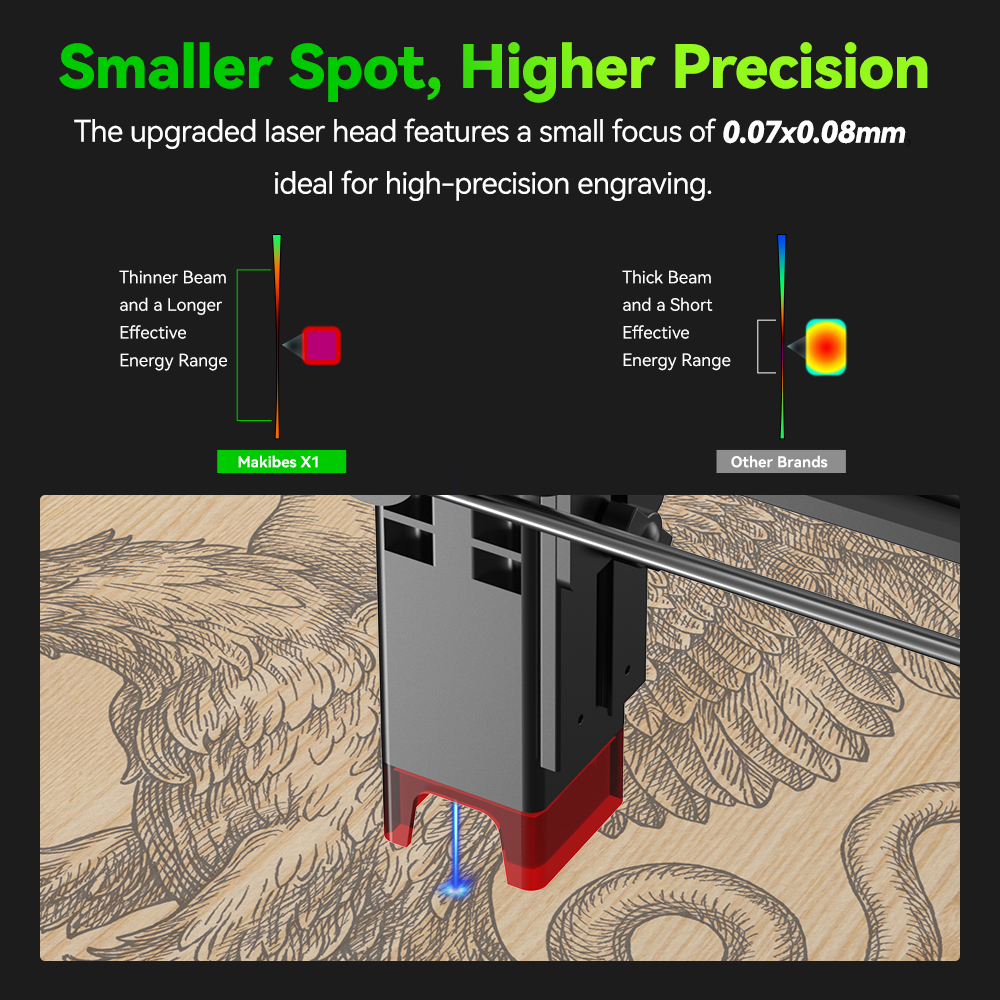

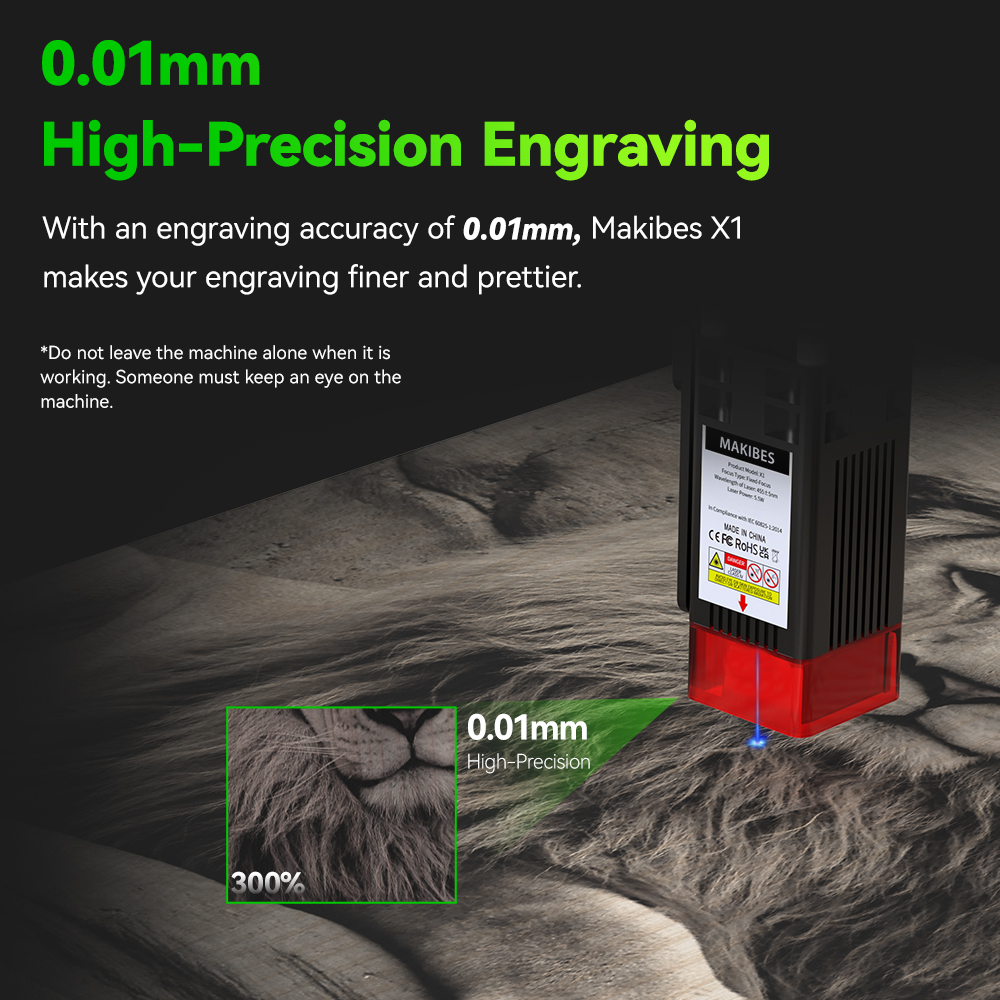

Upgraded Compressed Spot for High Precision

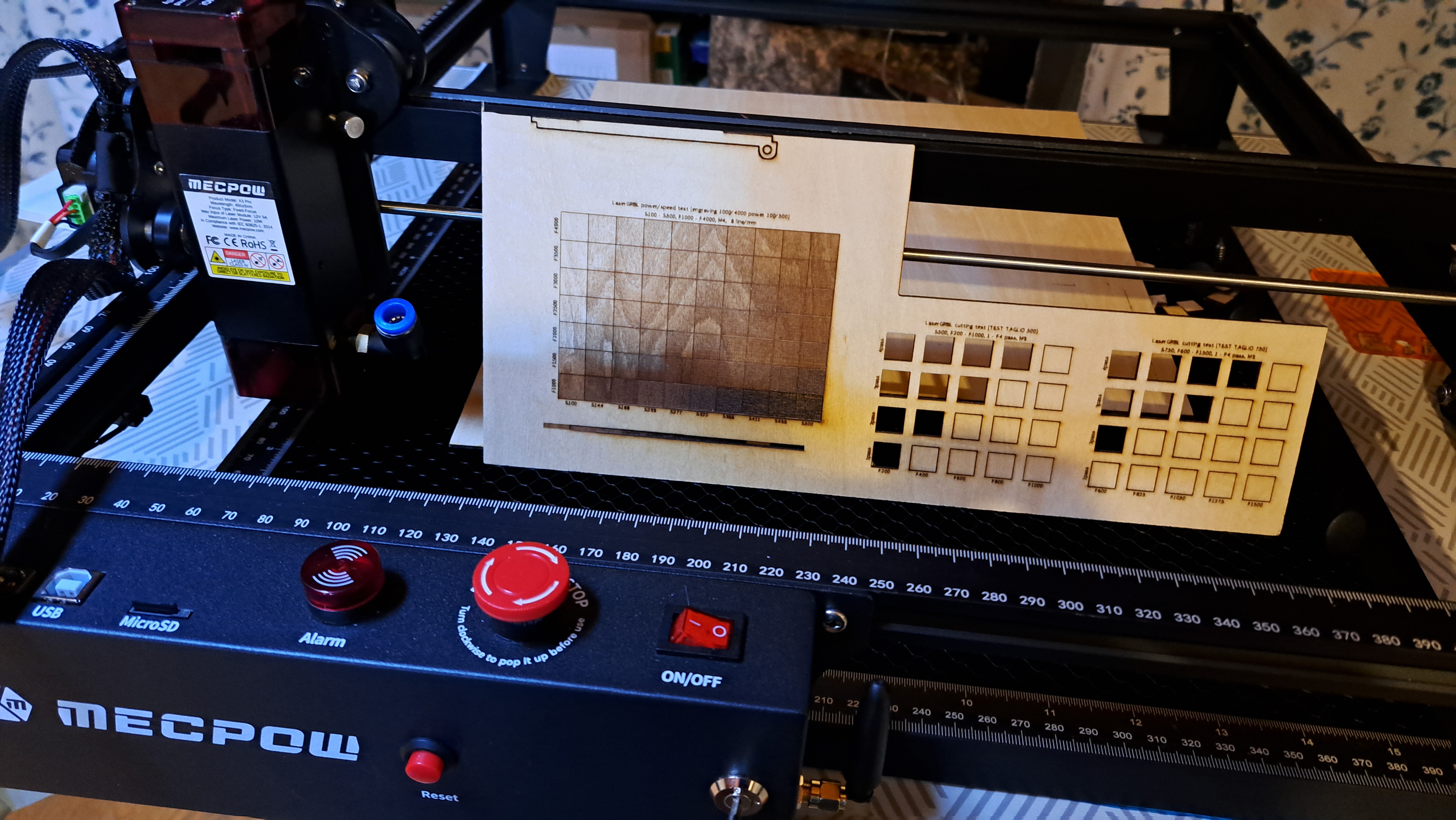

The Makibes X1 adopts a 5.5W diode laser with a small focus of 0.08mm and an engraving accuracy of 0.01mm. The small spot size, along with short pulses, produces high peak power, which can achieve more accurate and deeper engraving and cutting. It can cut a wood board with a 12mm thickness and an acrylic board with an 8mm thickness.

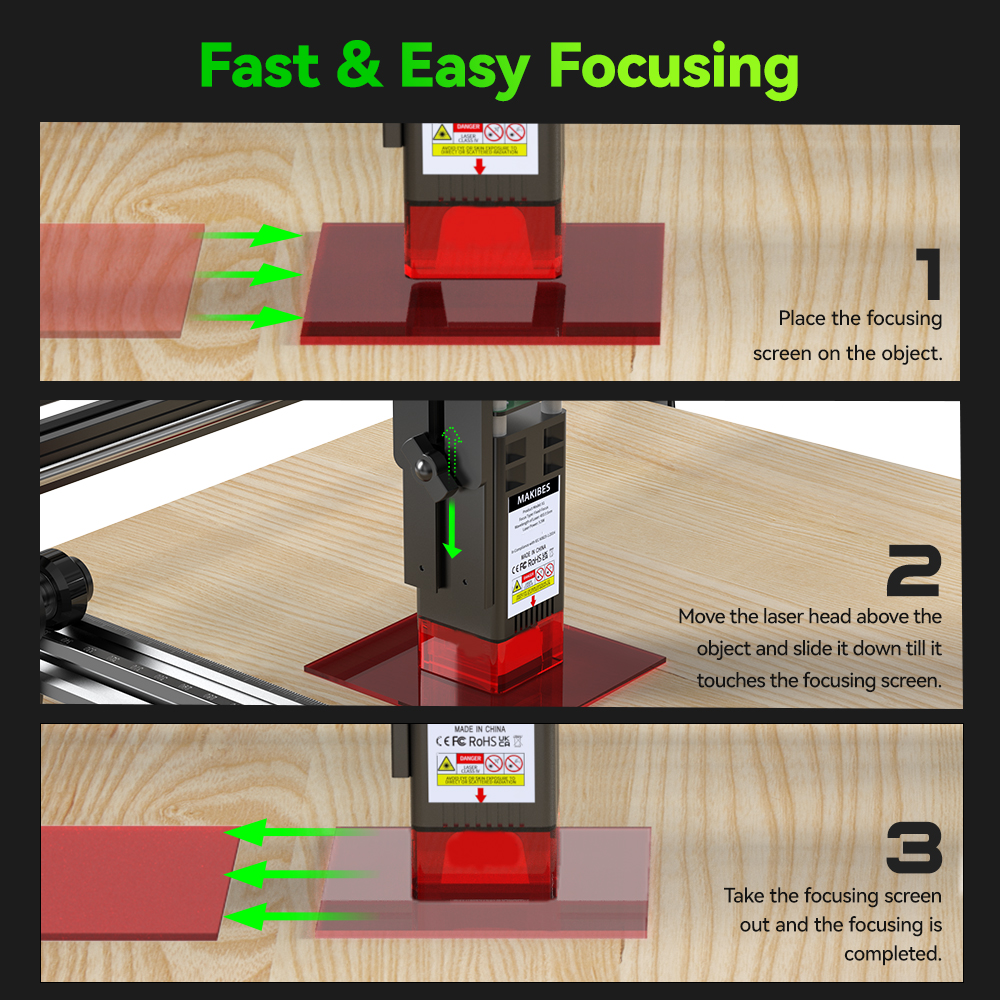

Fast & Easy Focusing

The X1 laser engraver comes with a fixed-focus laser that saves you time in adjusting the focus and a focusing screen that helps you move the laser head to the correct position. Slide down the laser head till it touches the focusing screen on the object and then remove the focusing screen.

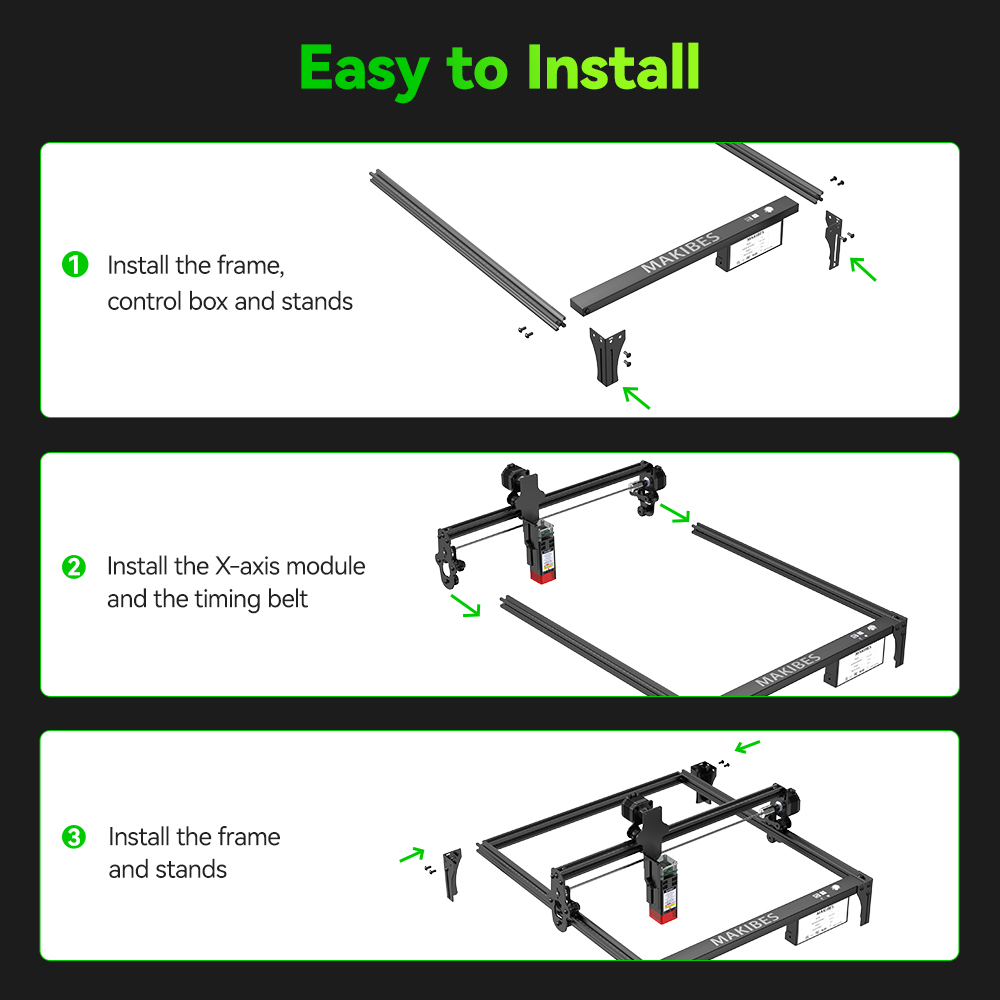

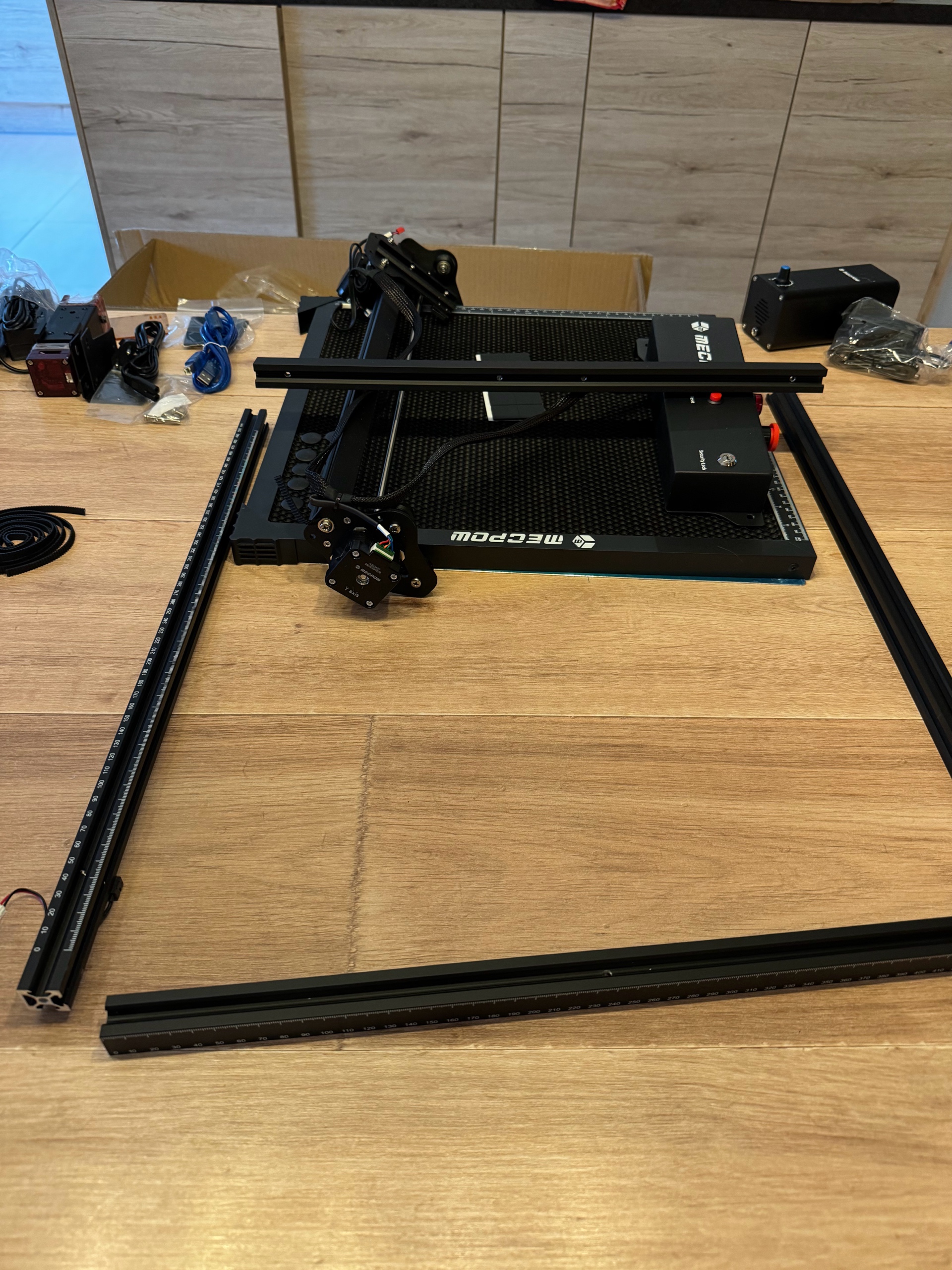

Sturdy Structure & Easy Assembly

With an all-metal structural frame, the Makibes X1 laser engraver is sturdy and durable, enabling stable and accurate engraving. The machine is in modular design, which can be assembled easily and quickly.

Eye Protection

The laser engraving machine is equipped with a laser shield on the laser module, which can filter out diffuse light from the laser spot to a large extent. A pair of laser safety goggles is also included for better eye protection.

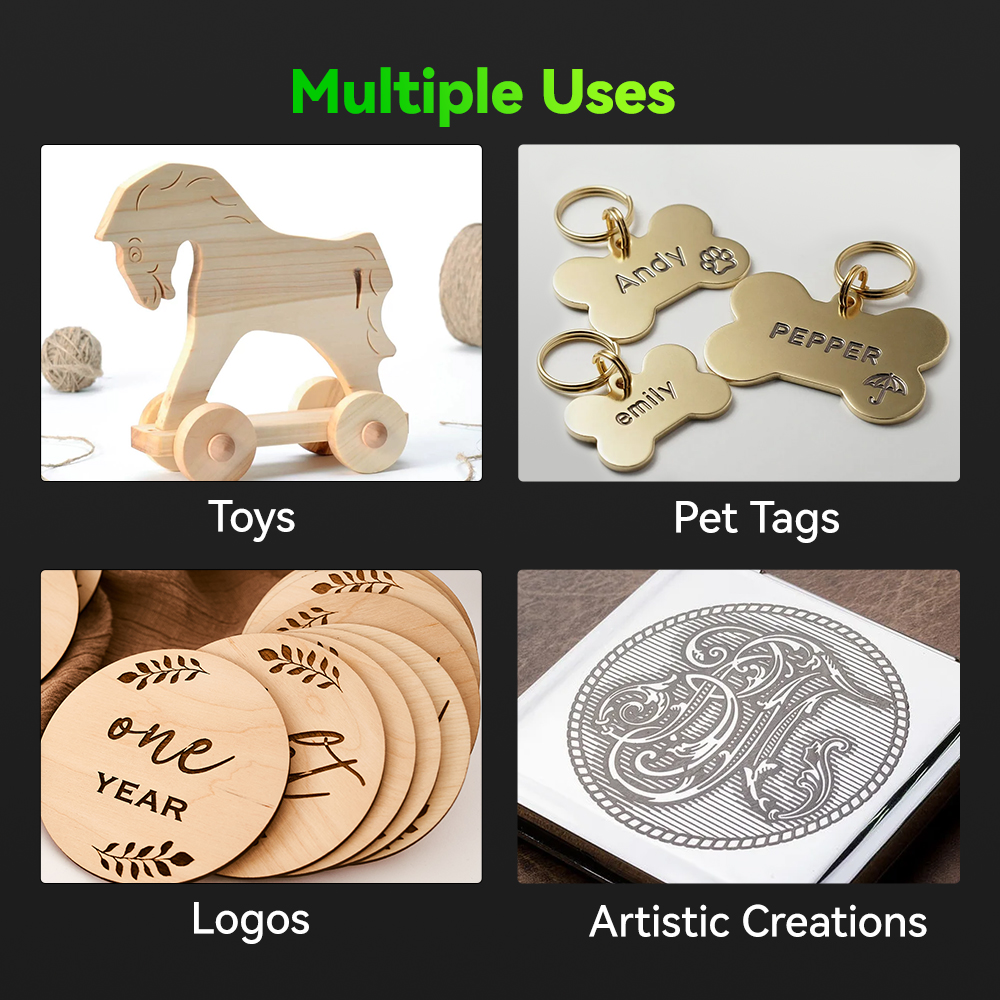

Wide Application and Compatibility

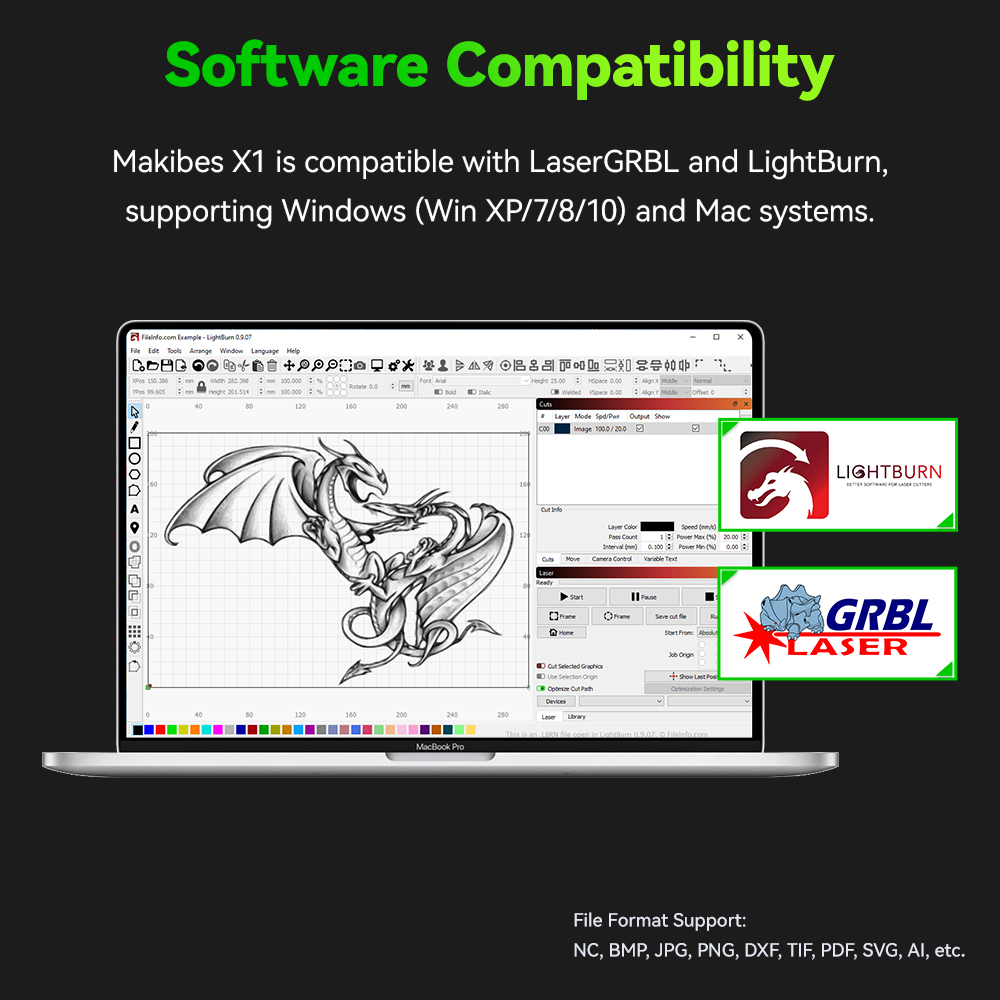

The X1 engraving machine can be used for engraving on a variety of materials, including wood, acrylic, leather, bamboo, fabric, stainless steel, etc. It is compatible with LaserGRBL (Windows only) and LightBurn (Windows & Mac OS), supporting various file formats, including JPG, PNG, DXF, TIF, PDF, SVG, AI, NC, BMP, etc.

Specification

|

General |

Brand: Makibes |

|

Specification |

Frame Material: Metal |

|

Weight & Size |

Product Weight: 3.66kg |

|

Package Contents |

1 x Laser Engraving Machine (Unassembled) |

Videos

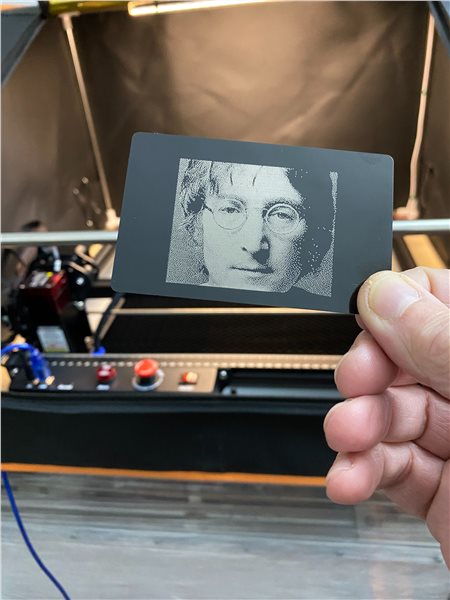

Customer Photos

Customer Videos

Customer Reviews

Questions & Answers

FAQ

Q1: What should I do when LaserGRBL fails to connect to the engraving machine?

A: 1. Caused by missing driver: In LaserGRBL, click "Tools" and “intallCH340 Driver” to install the driver. Reboot the software after installation and connect again.

2. Caused by incorrect port number selection: Select the right port number.

3. Caused by incorrect baud rate selection: Select the right baud rate - 115200.

4. When LaserGRBL is repeatedly opened with multiple extra interfaces turning up: Close the extra interfaces.

Q2: What can I do when “soft limit error” occurs in LaserGRBL?

A: Change the value of $20 to 0 at Grbl configuration.

Q3: How to connect the engraving machine to your computer via LightBurn?

A: First, click "Create Manually". Second, scroll down to GRBL and select it. Third, select "Serial/USB". Fourth, name it "GRBL X1" and enter "400" in the lengths of the X and Y axis. Last, set the origin to "Front Left. After creating your device, choose the right COM port.

Q4: How to fix misalignment and inaccurate results?

A: 1. Caused by improper tension of the timing belts: Set the tension of the timing belts correctly and keep all the timing belts under the same tension.

2. Caused by loosened screws or mechanical backlash: Tighten all the screws.

3. Caused by the engraving machine slipping and moving on the tabletop when it is working: Secure the engraving machine to avoid its movements.

4. When the laser module is not firmly screwed on its support: Tighten the laser module.

Q5: Will it cause damage to the eyes?

It is advisable that you wear the included protective Goggles when operating the Laser engraver. Furthermore, a fireproof enclosure will add another layer of protection to anyone working with the laser or anyone who stays close by.

Q6: Do we really need an air assist + air pump kit?

The air assist is not very much of a necessity. Because the Makibes X1 is a 5-watt laser engraver, meaning that it is mainly designed for laser engraving. If you use it for laser cutting, the air assist kit for Makibex X1 will be available in about 1-2 months. Only a puff of smoke will be generated during the process. If you use it for wood cutting, I would suggest a 10 - 20-watt laser engraver( The Makibes X2 10-watt version is on the way). These variants will have the air assist included.

Q7: Will it generate extra costs in the future?

I guess this is one of the commonest concerns of all our regulars or new users. The answer is "yes".

Most likely, you will need a honeycomb panel if you want to better protect your working table.

As a puff of smoke is inevitable, you may need a smoke exhaust box or enclosure as well if you find it hard to stand the smell.

If the 410*400mm engraving size is too small for your project, an expansion kit will do.

The above-mentioned accessories will add to something like $200. But it always pays off!